With the popularization of new energy vehicles, 5G smartphones, smart robots, high-speed servo motors, etc., and the rapid demand for rare earth terms such as high remanence (Br), high coercive force (Hcj), and high magnetic energy product (BH), our company has recently developed 50UH, 45EH, 40AH and other high-performance magnets, and aims to develop 54H, 52UH, 48EH, 42AH and other higher-performance magnets.

Different from the traditional NdFeB manufacturing process, our company has gradually adopted the grain boundary diffusion process to manufacture high-performance NdFeB magnets to reduce manufacturing costs. The DV (Tb) metal or metal compound attached to the surface of the magnet is thermally diffused under the vacuum and high temperature using different concentration steps to form Dv (Tb) 2Fe14B transition phase with high coercive force between the main phase and the neodymium-rich phase, which greatly improves the coercive force (Hcj) without affecting the residual magnetism (Br).

| Grade | Br(T) | Hcj(Koe) | BH max(MGoe) | Thicness magnetized |

|---|---|---|---|---|

| 50UH | 1.38-1.42 | > 25 | 48-51 | < 7 |

| 48UH | 1.36-1.4 | > 25 | 46-49 | < 9 |

| 45UH | 1.32-1.37 | > 25 | 43-45 | < 9 |

| 45EH | 1.32-1.37 | > 30 | 43-45 | < 5 |

| 42EH | 1.29-1.33 | > 30 | 40-43 | < 7 |

| 40EH | 1.25-1.3 | > 30 | 38-41 | < 9 |

| 40AH | 1.25-1.3 | > 35 | 38-41 | < 5 |

| 38AH | 1.22-1.26 | > 35 | 36-39 | < 7 |

| 35AH | 1.17-1.22 | > 35 | 33-36 | < 9 |

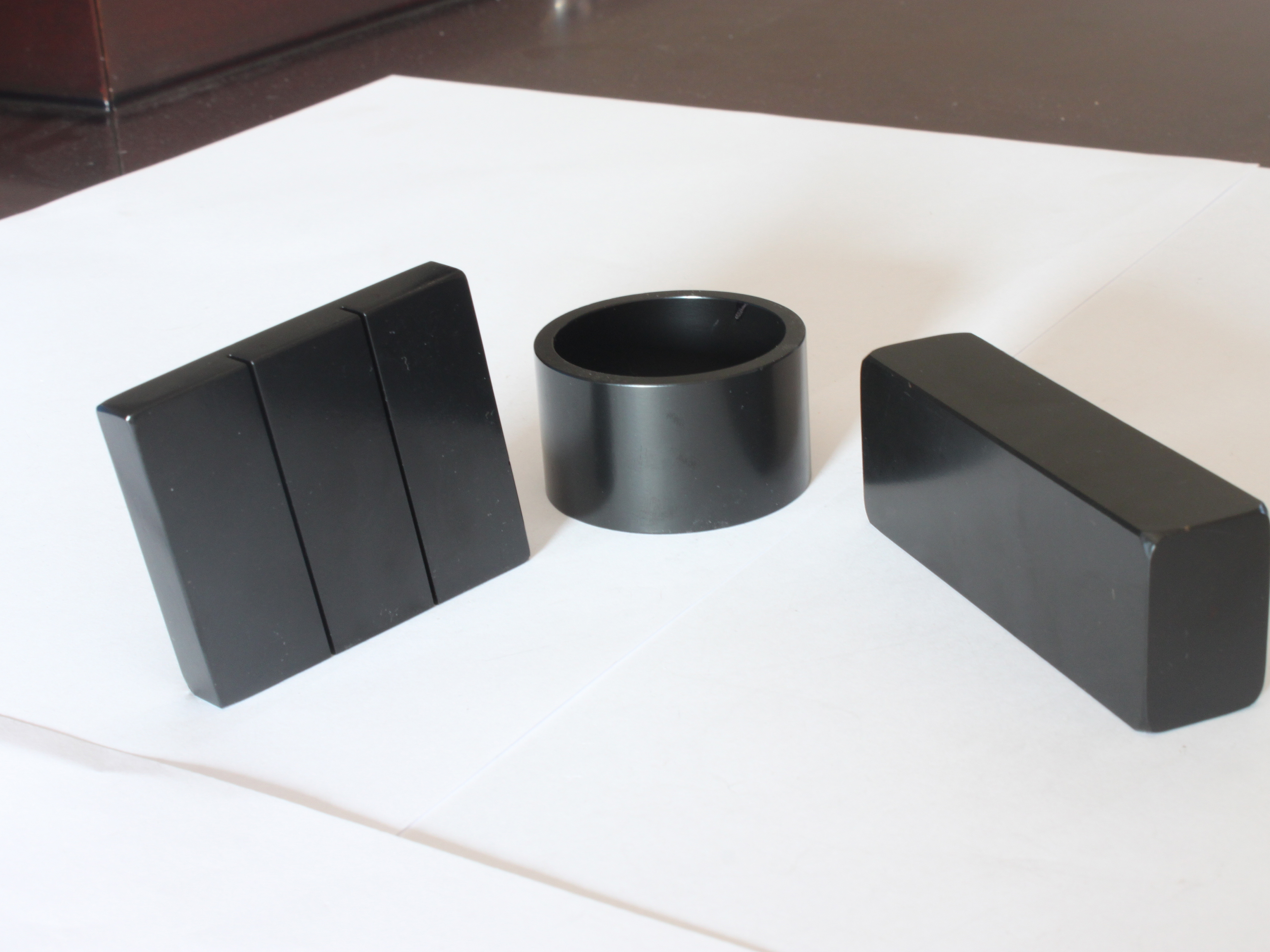

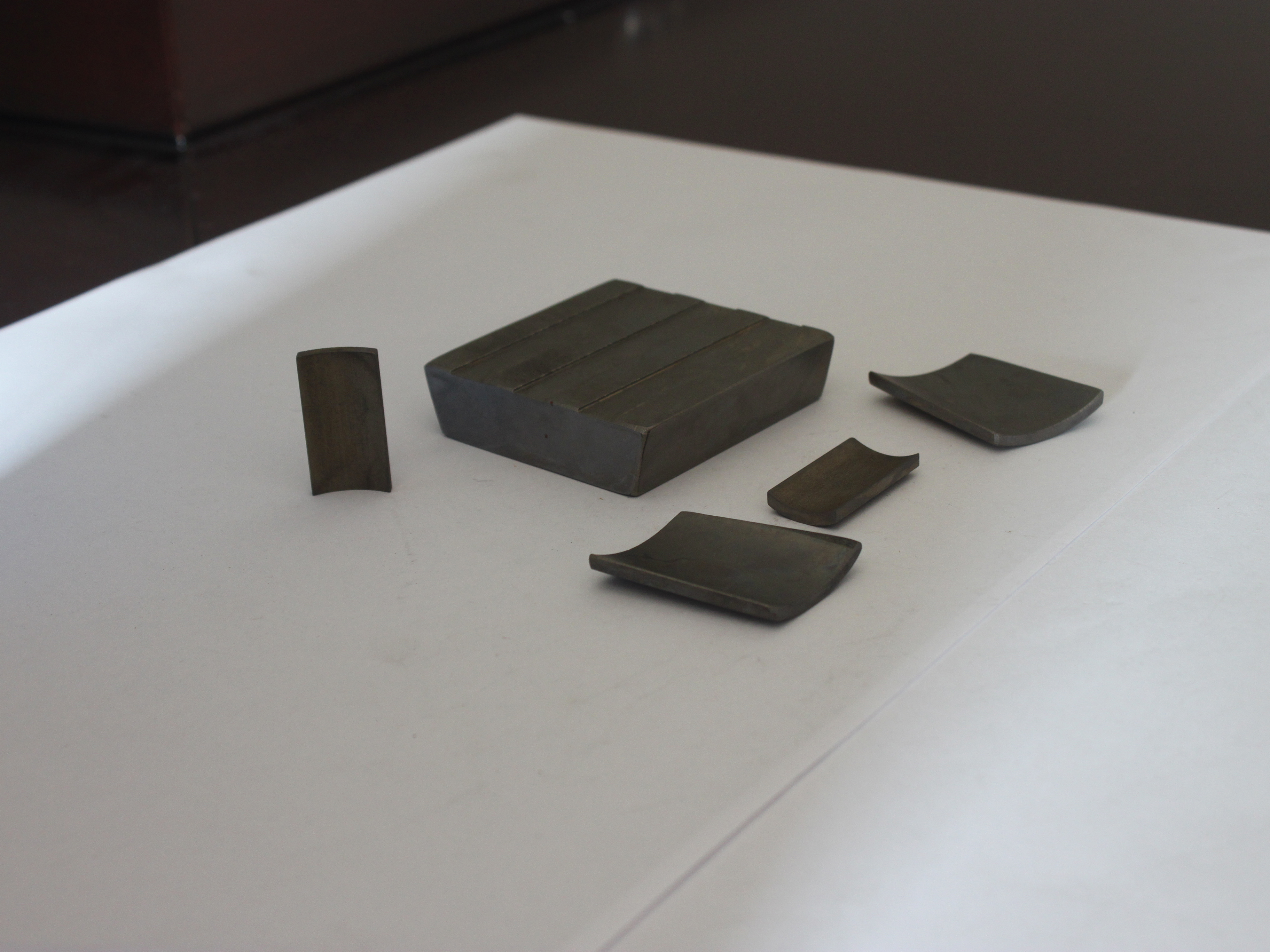

Black epoxy

Black Nickel

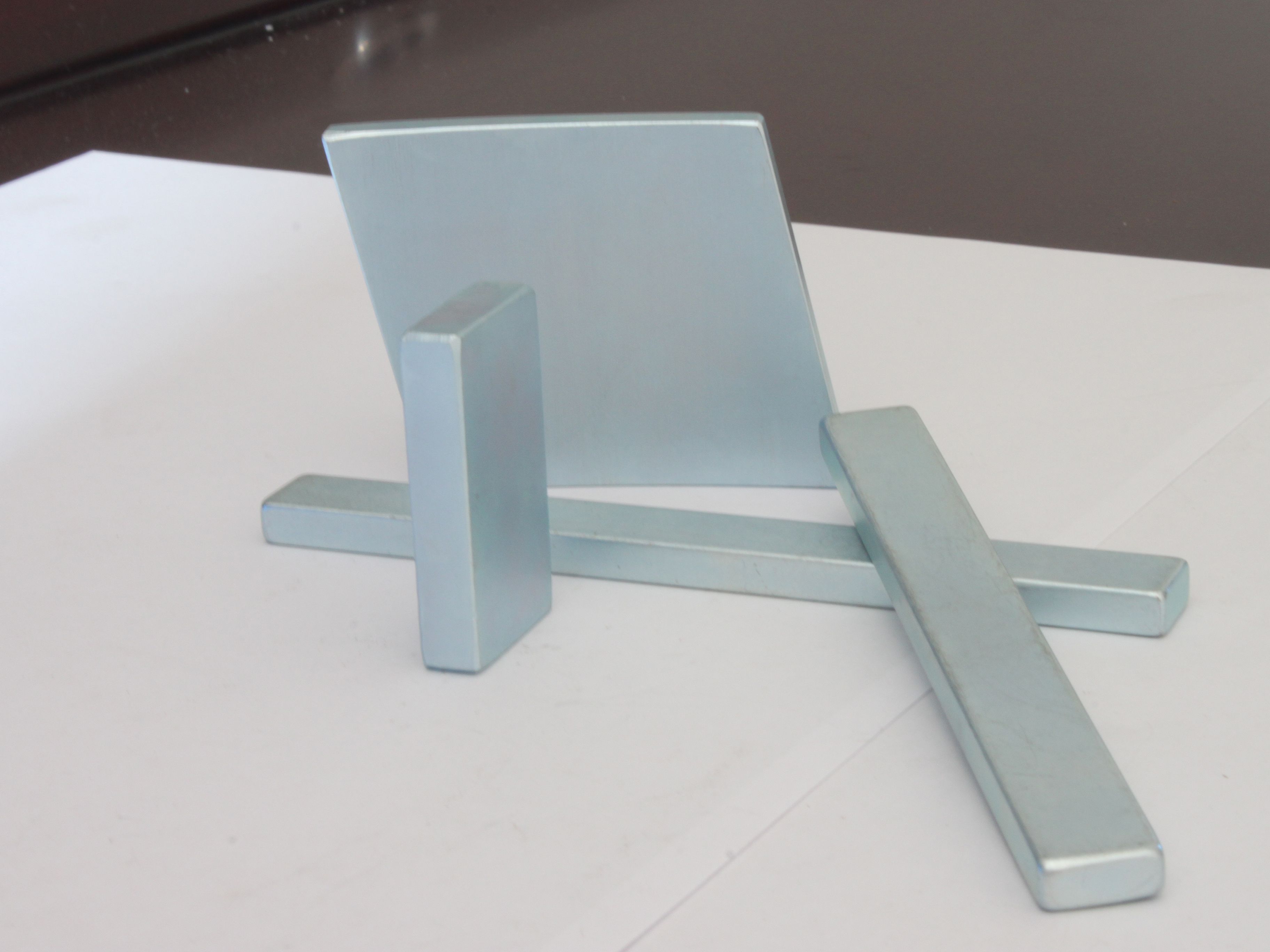

Blue & white Zn

Chromium

color Zinc

Epoxy

Everlube

Gold coating

Ni-Cu-Ni

Parylene

Phosphating

Silver

Teflon

Others